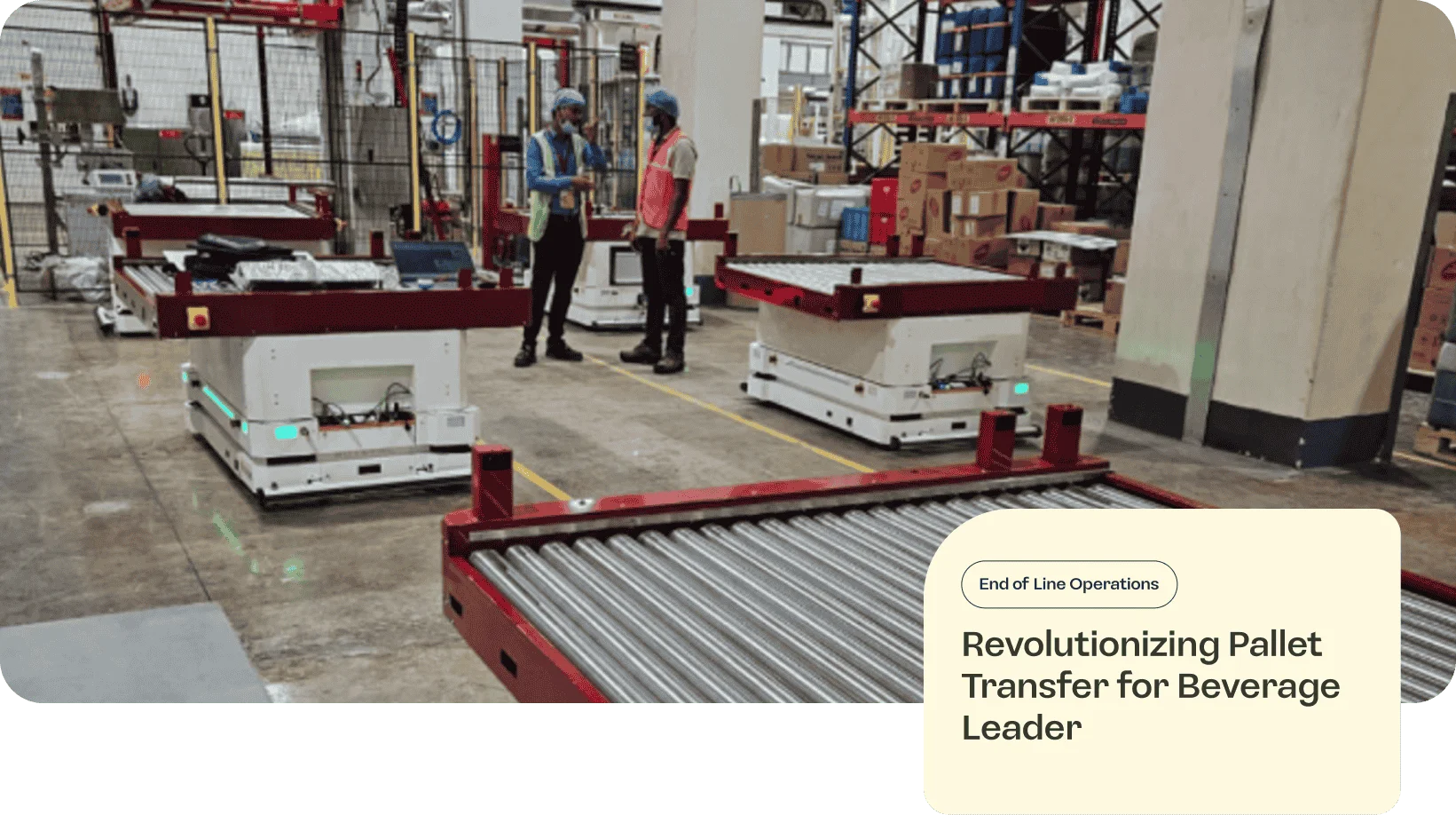

Autonomous Navigation & Safety

The MAG1000 AMR is equipped with an intelligent navigation system and safety sensors. A purple focus light in the front warns oncoming forklift drivers, and LED indicators on the sides signal different states - green for navigation, purple for docking, and orange for idle. This ensures safe and smooth operation in a dynamic factory environment.

Workflow Automation

Botsync’s no-code software platform SyncOS™ automates the workflow for pallet pick-up and drop-off. The operation is easily triggered by operators using a tablet interface, reducing manual intervention and simplifying the process.

Auto-Charging Feature

The AMR automatically returns to its home station when idle or when the battery drops below 25%, ensuring 24/7 uninterrupted operations.