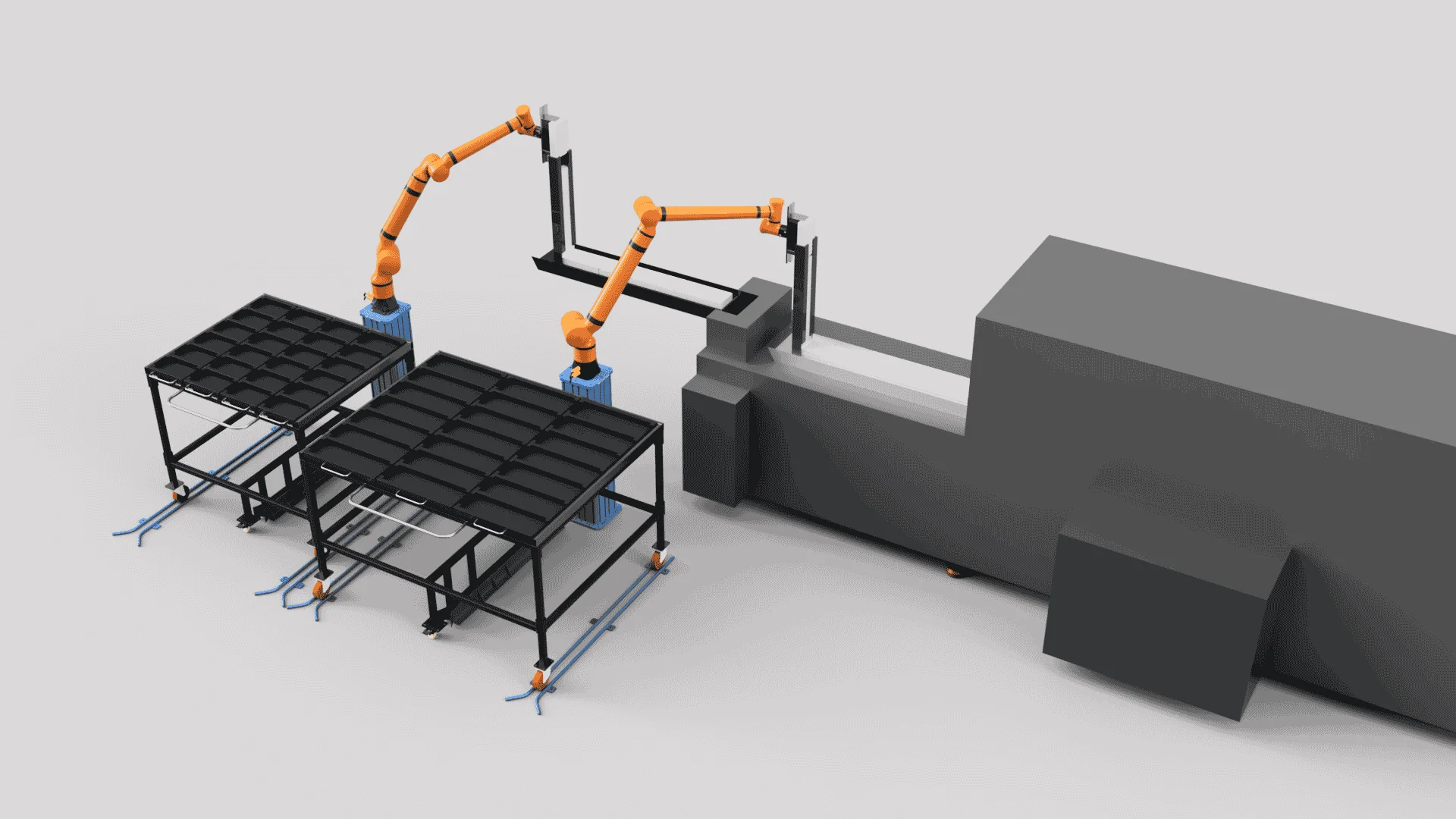

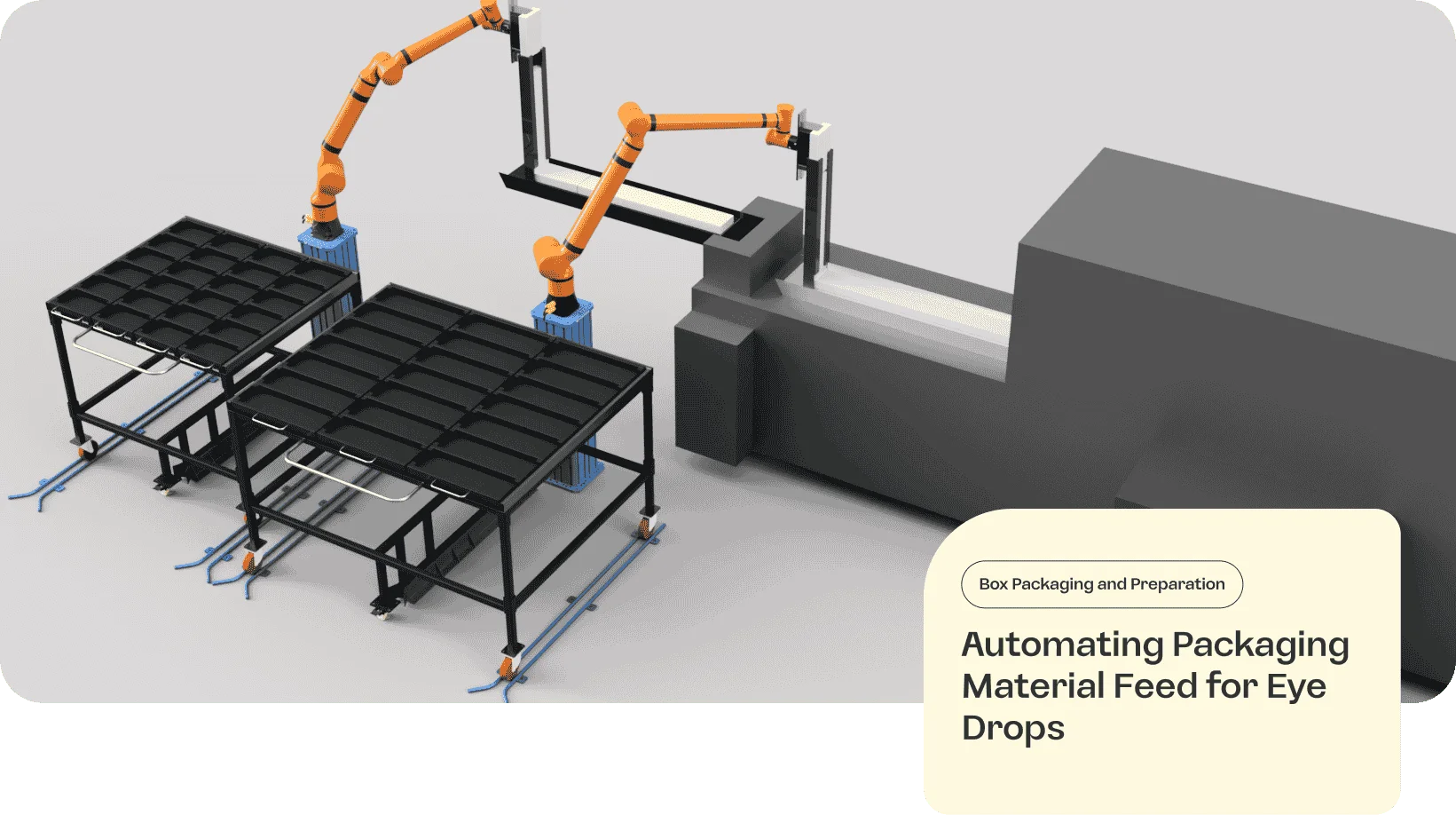

Automating the Feed of Packaging Materials for Eye Drop Manufacturing

Our client is a global leader in eye care, with a legacy spanning over 75 years. Operating in 60 countries and serving patients in over 140, itt stands as the largest eye care device company worldwide, with expertise across Surgical and Vision Care.

The Problem

The packaging machine in our client’s eye drop manufacturing facility is designed to bundle six cartons together in a seamless process, including:

- Inserting eye drops into a carton box.

- Placing a leaflet into the box.

- Closing the carton and wrapping the bundles with plastic.

With a capacity of 300 products per minute, the machine had the potential for high throughput. However, manual operations required operators to place flat cartons and leaflets into the in-feed every minute, across three shifts. This led to the machine running below capacity, producing only 150–200 products per minute.

Key issues affecting operational efficiency included:

- Underutilization of Packaging Machine: The machine’s capacity wasn’t fully leveraged.

- Lower Productivity and Throughput: Output was limited due to the dependency on manual feeding.

- Continuous Manual Involvement: Operators had to perform repetitive tasks every minute, reducing overall efficiency.

Our Solution

Botsync automated the in-feed process using:

This automation success story underscores Botsync’s ability to optimize end-of-line packaging operations, helping manufacturers unlock their machines' full potential.

Machines and Systems Used -

- Kassow Cobots with customized end effectors.

- Safety Curtain for operational safety.

- Vertical Storage Carousel for material handling.

- SyncOS Integrator for system management.